In a significant setback, General Motors (GM) has announced a temporary suspension of vehicle production at two pivotal U.S. facilities due to the supply chain impact inflicted by Hurricane Helene. This unprecedented halt primarily affects production lines dedicated to the lucrative large pickup and SUV segments, which are crucial to GM’s bottom line. As natural disasters increasingly disrupt operations globally, companies must adapt and strengthen their supply chain resilience, an area just brought to the forefront of GM’s operational strategies.

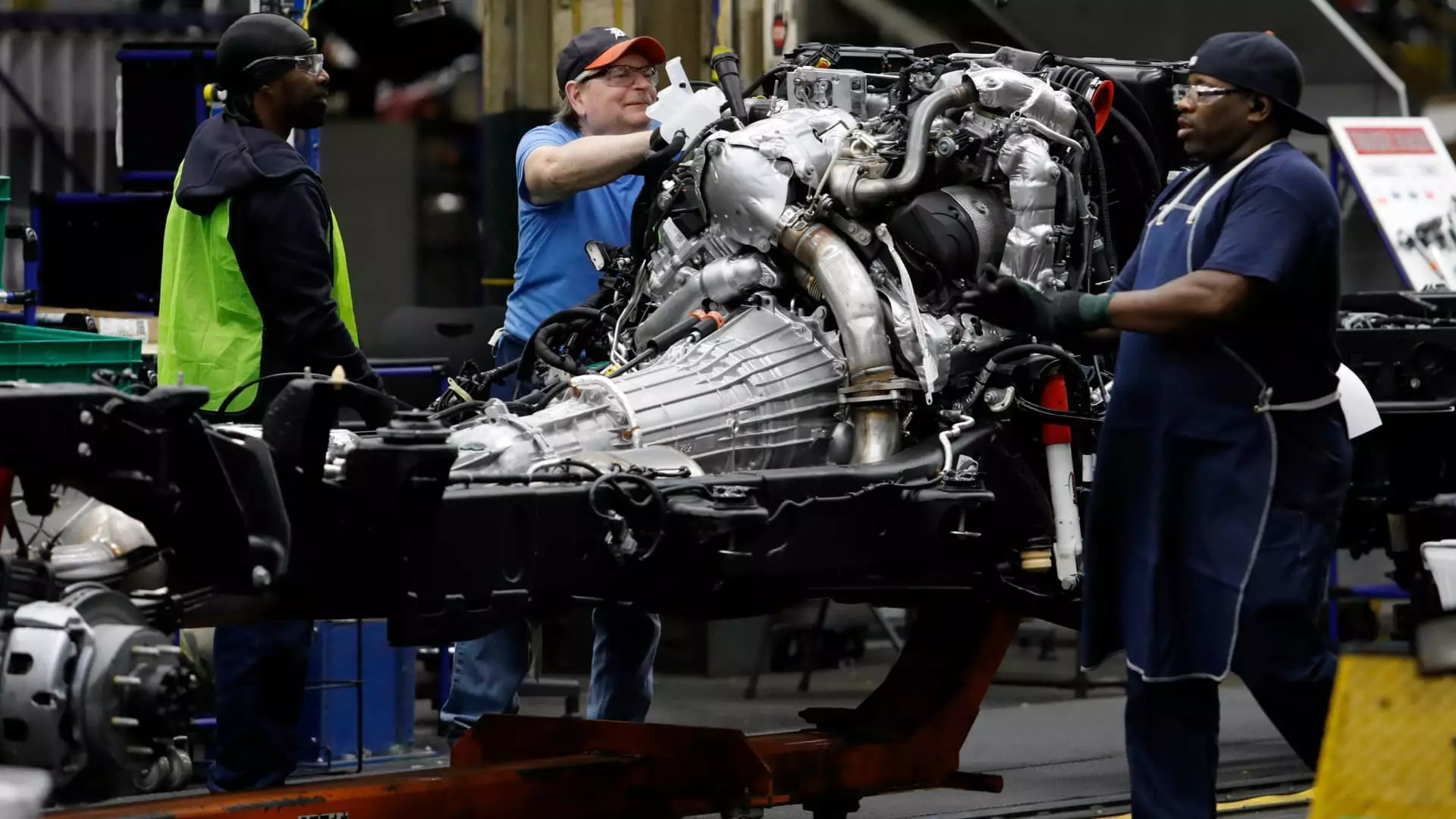

The halt in vehicle assembly occurred at GM’s Flint, Michigan plant, known for producing heavy-duty trucks, alongside the Arlington Assembly in Texas, responsible for full-size SUVs such as the popular Chevrolet Tahoe and luxurious Cadillac Escalade. The cancellation of several production shifts highlighted the vulnerability of automakers to external factors, such as severe weather events. Internally, GM’s communications to employees indicated a cautious approach to resuming production, aiming for a safe and efficient restart while navigating the challenges posed by Hurricane Helene’s aftermath.

The ramifications of Hurricane Helene extend beyond GM’s immediate production challenges. The storm made landfall in Florida, devastating regions in the southeastern U.S. and parts of North Carolina, leading to a tragic loss of life. With over 215 individuals reported deceased and a significant number still unaccounted for, the human element of such events cannot be overlooked. For GM, the impact on suppliers serves as a stark reminder of how interconnected and fragile supply chains can be, especially in the wake of natural disasters.

In light of these challenges, GM’s Vice President of Global Purchasing and Supply Chain, Jeffrey Morrison, emphasized the dual threats posed by Hurricane Helene and a concurrent dockworkers’ strike, which further complicated logistics. The recent history of disruptions, particularly during the COVID-19 pandemic, led GM to overhaul its supply chain management, enhancing their ability to monitor sub-tier suppliers more effectively. Morrison noted the pandemic acted as a catalyst for deeper introspection, allowing GM to establish a comprehensive inventory of suppliers and potential points of failure within their supply chain ecosystem.

As GM grapples with these operational challenges, they are actively working with affected suppliers to swiftly restore normalcy. A crucial aspect of their strategy is to lend support to their suppliers during these disruptions, indicating a collaborative spirit within the industry. By leveraging stronger relationships and improved supply chain visibility, GM aims to mitigate future disruptions and enhance the resilience of their production processes.

The recent operational disruptions experienced by General Motors serve as a vital case study on the importance of robust supply chain management. As weather patterns become more unpredictable and external factors increasingly influence manufacturing processes, the necessity for automotive companies to bolster their resilience and adaptable strategies is paramount. The lessons learned during this period of upheaval will undoubtedly play a critical role in shaping the future of production and supply chain management in the face of adversity.